The load of wheel bolts is much greater than that of household cars, and daily inspections need to pay more attention to the fastening status, wear and corrosion, and potential fracture hazards. Moreover, trucks are mostly twin tire structures, and additional inspections of the inner tire bolts are required. The specific and simple steps are as follows:

Preparation

- Parking regulations: Park the vehicle on a flat and hard surface, tighten the handbrake, shift into neutral, and use triangular blocks to support the front and rear wheels to prevent slipping; If it is a trailer, it is necessary to do a good job of parking brake and support protection.

- Cleaning: Use a high-pressure air gun (or a hard bristled brush+cloth) to clean the soil, sand, and oil stains on the surface of tire bolts, nuts, and wheel hubs to avoid impurities blocking cracks, looseness, and other issues.

- Safety protection: When checking the inner tire bolts, a flashlight can be used for illumination, and gloves should be worn if necessary to prevent oil stains and scratches.

Visual comprehensive inspection

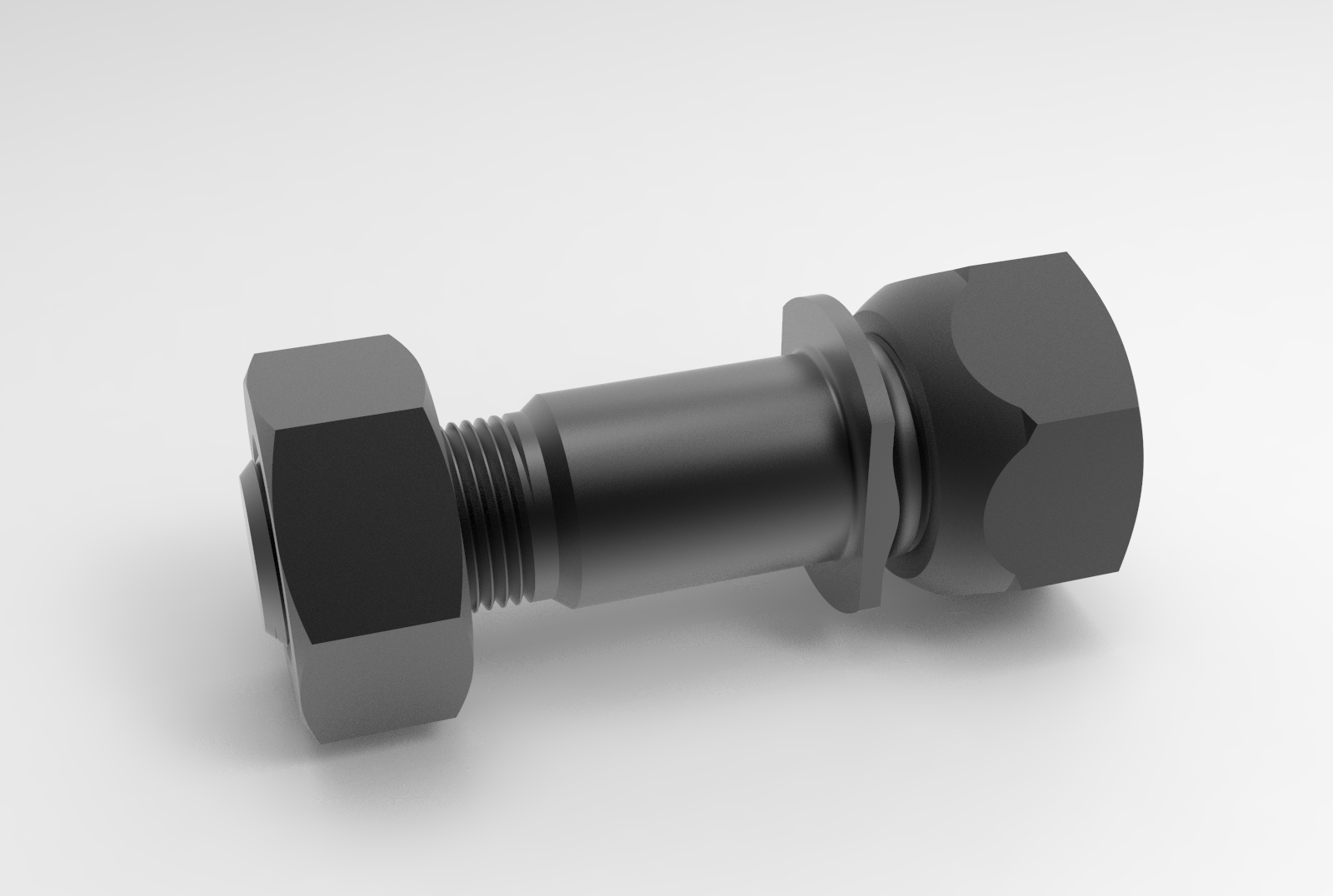

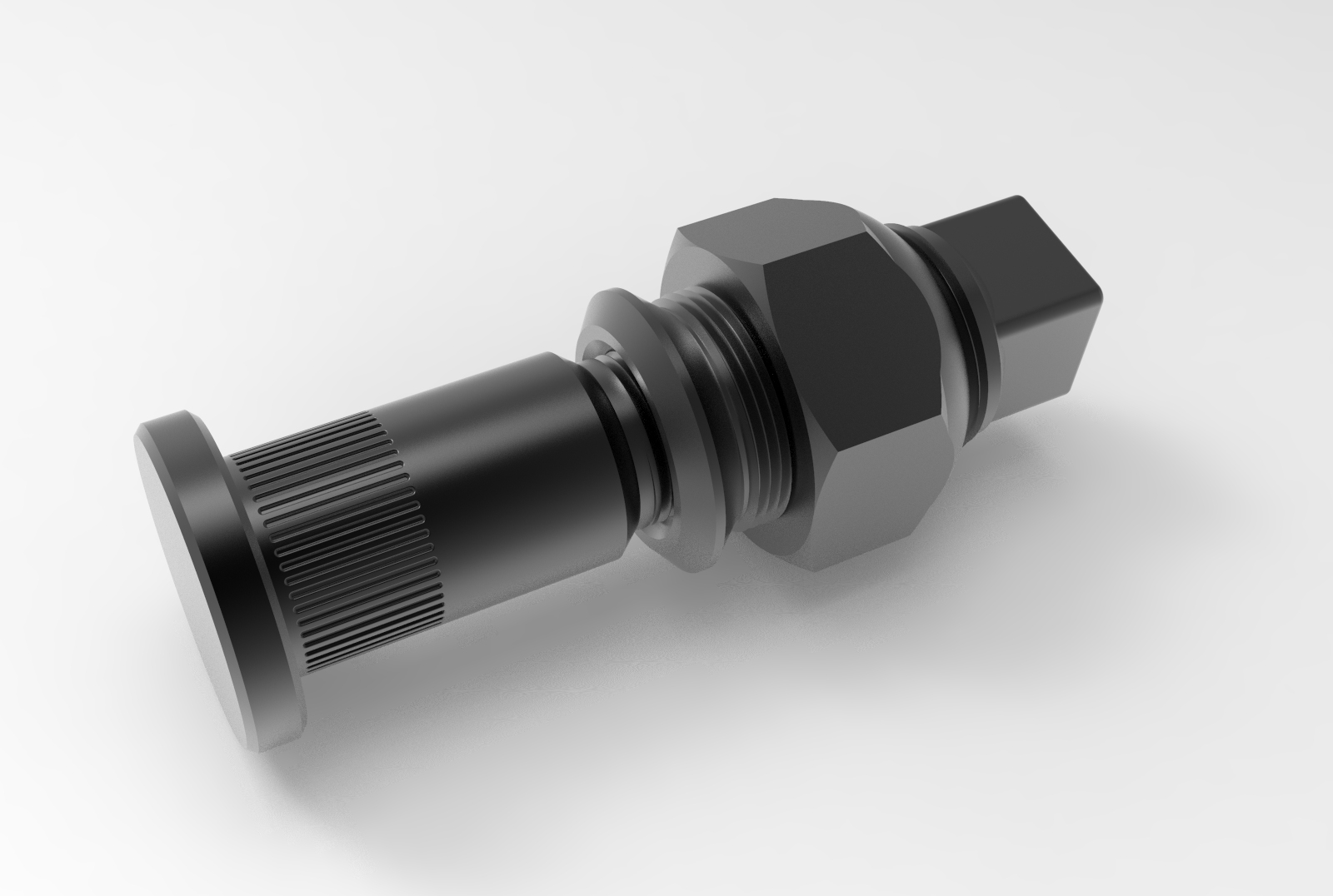

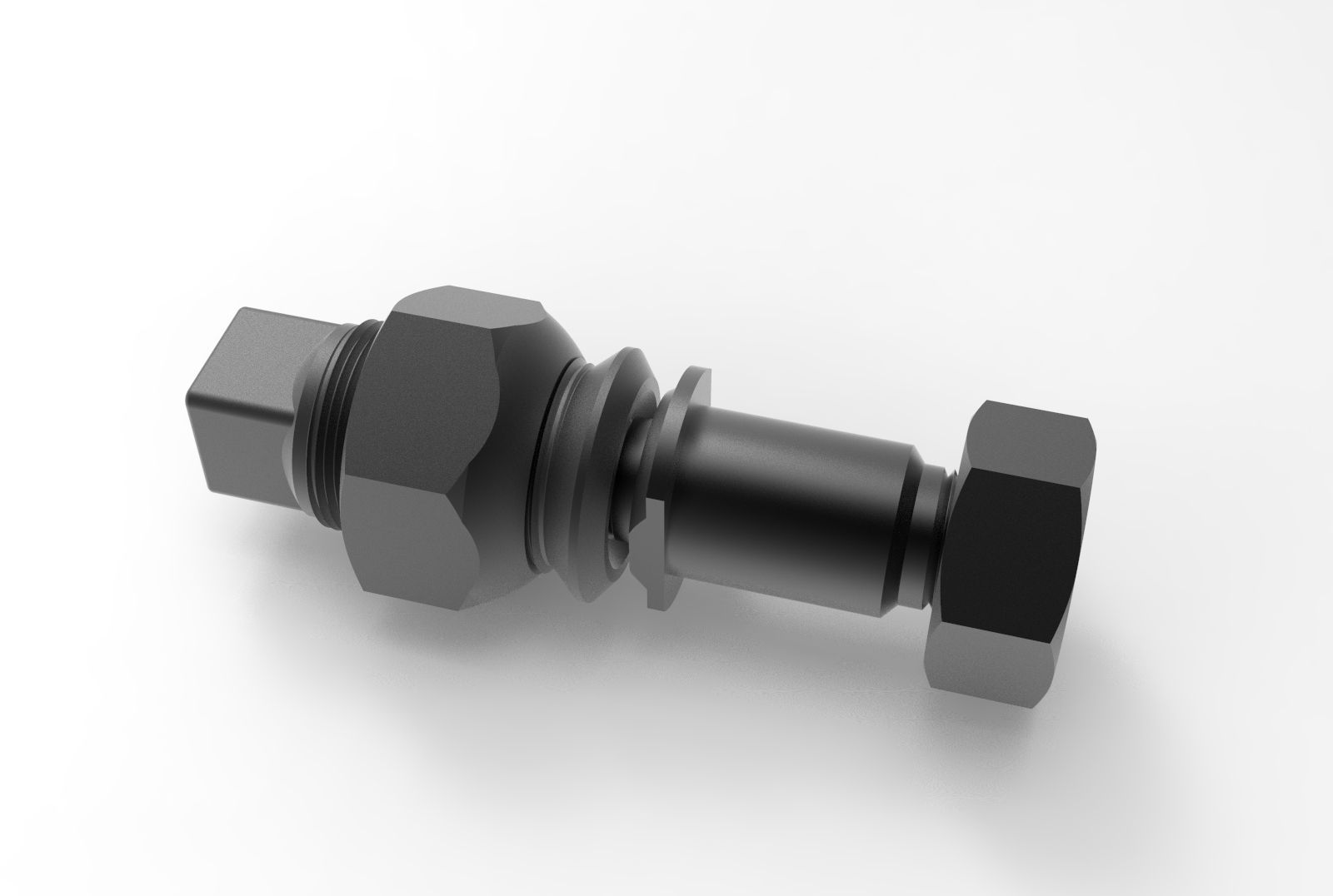

- Inspect all bolts/nuts: check one by one for cracks, deformation, loose teeth, missing threads, and whether the threads are complete; Observe whether there is severe rust on the surface (rust penetrating the threads, rust on the corners of the nut) or gaps between the nut end face and the wheel hub.

- Double tire installation special inspection: Focus on checking the bolts of the inner tire, as the inner position is concealed and loose or damaged is more likely to be overlooked; Simultaneously observe whether there is any abnormal misalignment between the inner and outer tires, which may be caused by loose bolts.

- Check for abnormal traces: Check for oil leakage near the bolt, which may affect the tightening force of the bolt; Check if the wheel hub is deformed, as deformation can exacerbate uneven stress on the bolts.

Attention: Do not use a sledgehammer to strike the wrench or forcefully twist it, otherwise it may cause the bolt to stretch and deform, and bury the hidden danger of fracture.

Recheck after driving

After driving the vehicle for 100-200 kilometers (especially on heavy or bumpy roads), stop and cool down to room temperature, and then recheck the feel of all tire bolts again, as the vibration during heavy driving can easily cause bolts to loosen.

Abnormal situation handling

- Loose bolts: They must be tightened with a torque wrench according to the manufacturer’s specified torque, and it is forbidden to tighten them based on experience; The bolts for twin tire installation should be cross tightened to ensure even force distribution.

- Bolt cracks, severe rust, and loose threads: Replace immediately, and it is recommended to replace them in pairs (bolts around the same damaged wheel hub may also have hidden damage). After replacement, tighten according to standard torque and do not drive with defects.

Post time: Jan-23-2026